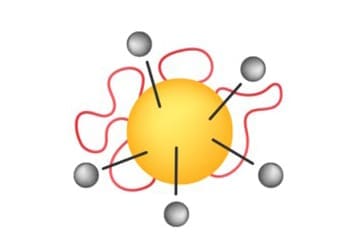

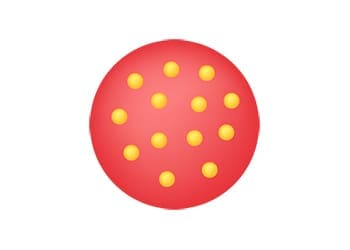

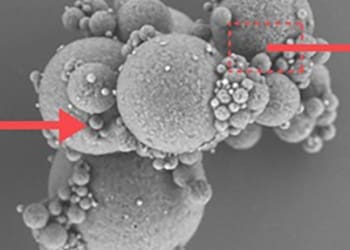

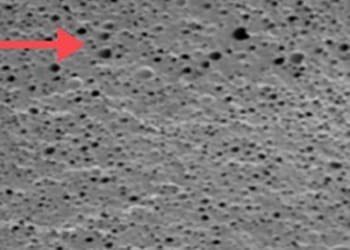

Preserving the nutritional value, bioavailability, taste, and shelf life of ingredients, especially oils, proteins, vitamins, and minerals, is a complex task. Micro-encapsulation helps food companies in the application of these sensitive nutritional ingredients. We are specialized in producing micro-encapsulated ingredients in powder form for the food, baby food, and medical nutrition industry. Alongside encapsulated oil powders, we can also dry pre-biotic powders or pro-biotic powders. High protein level ingredients are also possible.

Micro-encapsulation

Preserve nutritional value, bioavailability, and shelf life, all at the same time

Scroll to read more